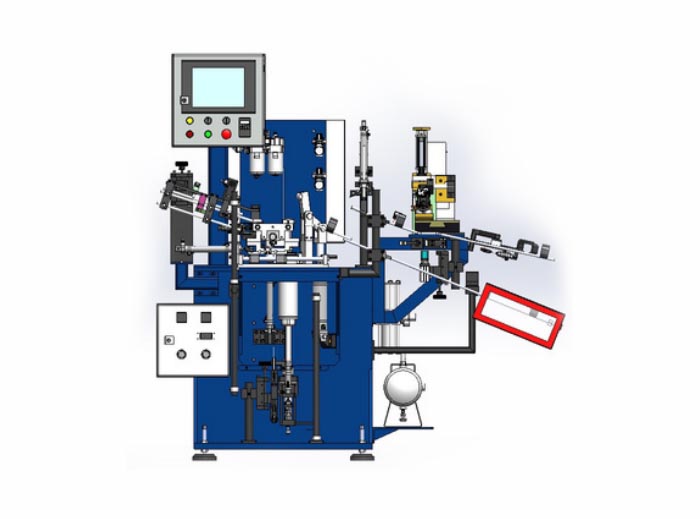

In an industrial landscape where differentiation, efficiency, and precision are paramount, standard off-the-shelf machinery often falls short. When your production process demands unique solutions that address very specific bottlenecks, complex assembly, or highly specialized tasks, a Special Purpose Machine (SPM) is the answer.

At SLOG SQUARE in Bawal, Haryana, we are master innovators in the field of industrial automation. We specialize in the design, engineering, and manufacturing of custom-built Special Purpose Machines that integrate seamlessly into your existing operations. Our SPMs are meticulously crafted to solve your most challenging production problems, delivering unparalleled accuracy, efficiency, and a significant competitive advantage.

Our capabilities in Special Purpose Machine design and manufacturing are broad and specialized, enabling us to tackle complex challenges across various industries. Our specific areas of expertise include:

Description: Custom-built systems for precise and high-speed assembly of multiple components into a finished product or sub-assembly. From manual workstations with automated assistance to fully robotic assembly cells

Applications: Automotive parts, electronic components, medical devices, consumer goods, white goods assembly.

Description: SPMs designed for automated, precise bending of various materials (e.g., metal sheets, tubes, wires) to complex geometries, often incorporating robotics or advanced tooling.

Applications: Fabrication, automotive exhaust systems, furniture manufacturing, appliance production.

Description: Custom solutions for high-precision cutting, shearing, punching, or trimming of materials like metal, plastic, rubber, or composites, tailored to specific product shapes and throughputs.

Applications: Component manufacturing, material preparation for assembly, continuous process lines.

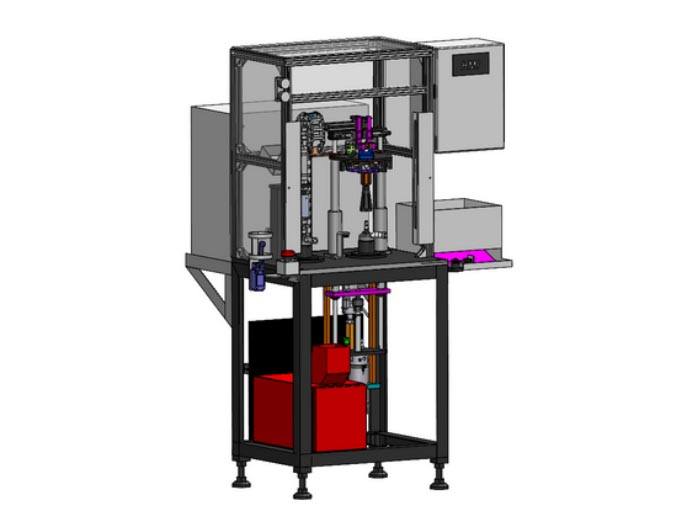

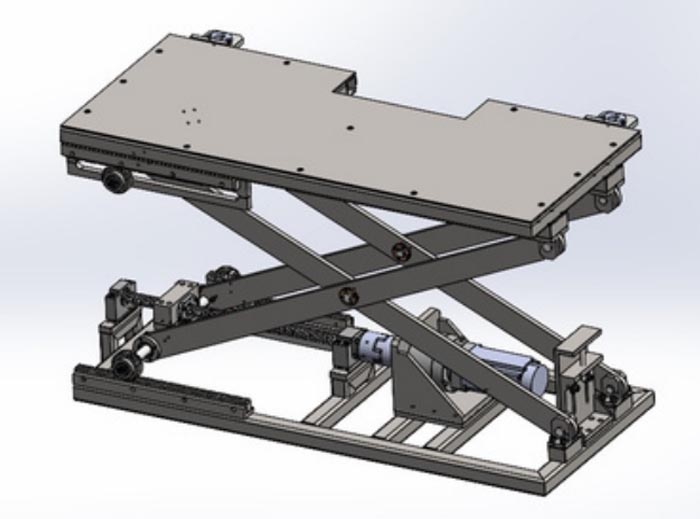

Description: SPMs that leverage hydraulic power for high force, heavy lifting, pressing, forming, or clamping applications, offering robust and controlled motion.

Applications: Metal forming, deep drawing, pressing, heavy assembly, testing machines requiring high force.

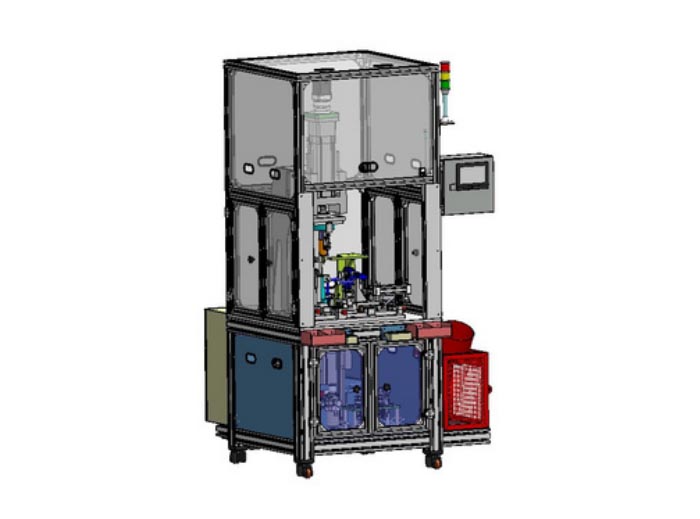

Description: Automated systems designed to precisely detect leaks in components or sealed products, ensuring product integrity and preventing defects.

Applications: Automotive parts (fuel tanks, engine components), medical devices, sealed food packaging, valves, and fluid systems.

Description: SPMs utilizing compressed air for fast, repetitive, and light-to-medium force operations such as clamping, pushing, pick-and-place, or simple indexing.

Applications: Fast assembly, product rejection, light material handling, automated jigs and fixtures.

Description: Custom machinery for specific refining or processing stages of materials, often involving crushing, grinding, mixing, or separating, tailored for unique product characteristics.

Applications: Chemical processing, mineral processing, specialized food processing, material reclamation.

Description: SPMs incorporating highly precise servo motors and drives for extremely accurate, dynamic, and controllable motion, ideal for complex multi-axis movements and synchronization.

Applications: High-speed packaging, precision assembly, robotic guidance, complex camming motions, high-accuracy positioning.

Description: Automated equipment designed to correct deformities or ensure flatness/straightness of elongated materials (e.g., rods, bars, tubes, profiles).

Applications: Metal manufacturing, wire drawing, component preparation.

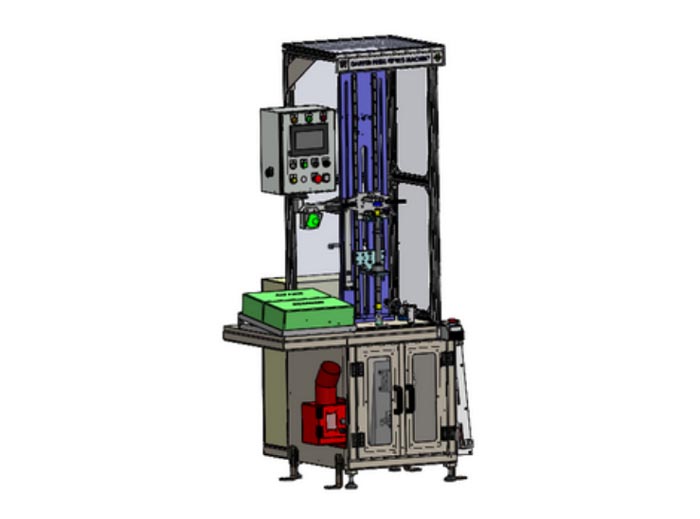

Description: Custom-built systems for automated quality control, functional testing, dimensional checks, visual inspection (often with vision systems), and performance validation of products or components.

Applications: End-of-line testing, in-process quality checks, automotive testing, electronics testing, pharmaceutical product verification.

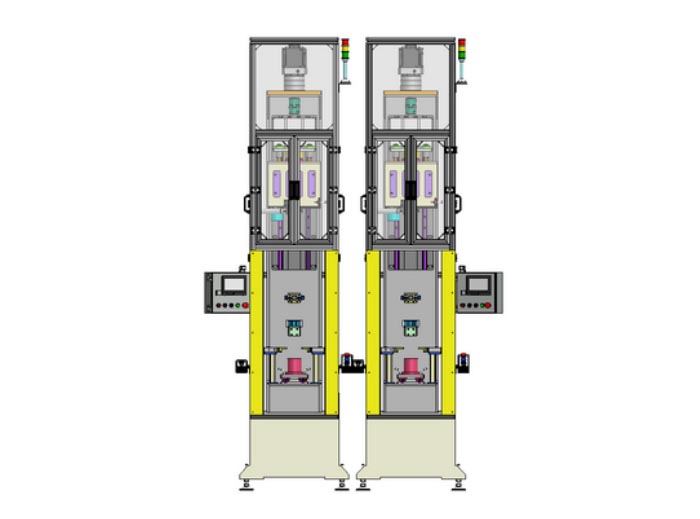

Description: Automated systems for precise and consistent tightening of fasteners (screws, nuts, bolts) to specified torque values, often with torque monitoring and data logging.

Applications: Automotive assembly, electronics assembly, appliance manufacturing, any product requiring accurate fastening.

Description: SPM that integrate automated welding processes (e.g., TIG, MIG, Resistance, Laser welding) with precision part positioning and clamping to achieve consistent, high-quality welds.

Applications: Automotive frames, structural components, appliance parts, specialized fabrication, often combined with robotic work cells.